Fill in the mailbox:

rosie.xiao@ylfrp.net

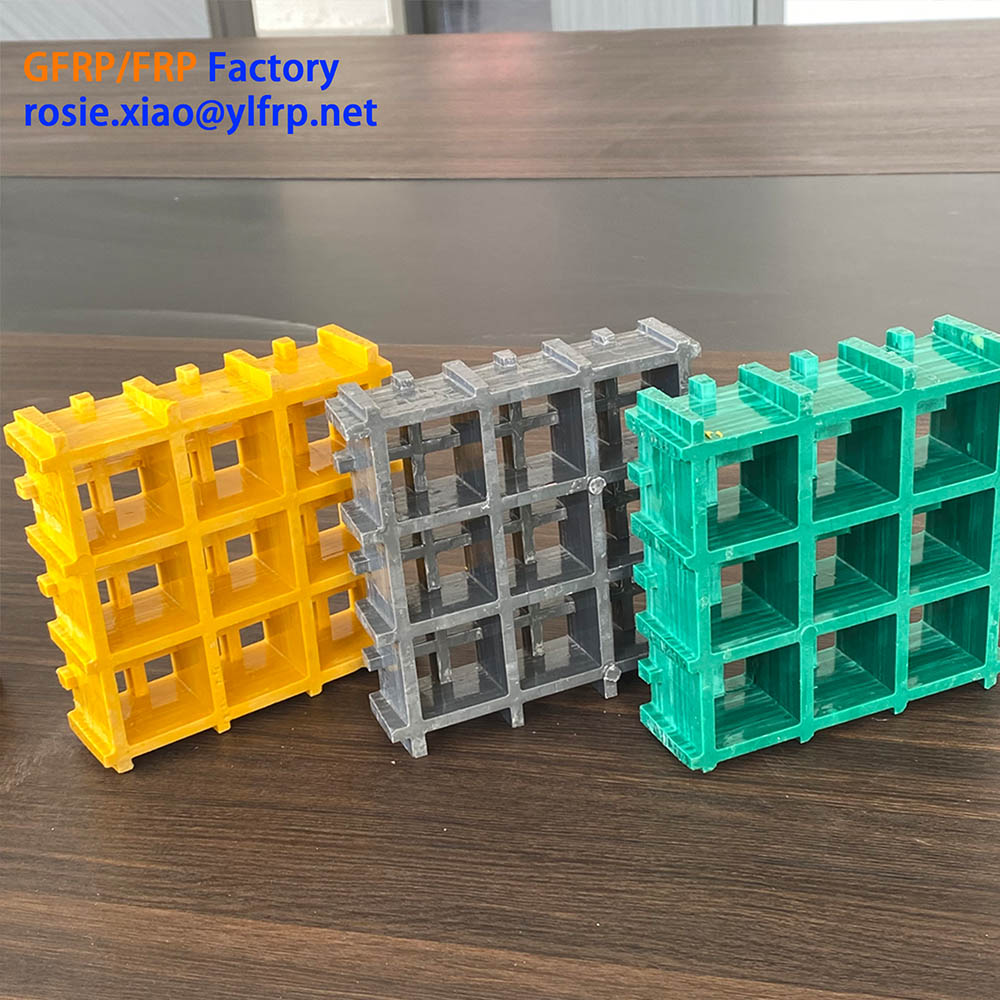

FRP Grating

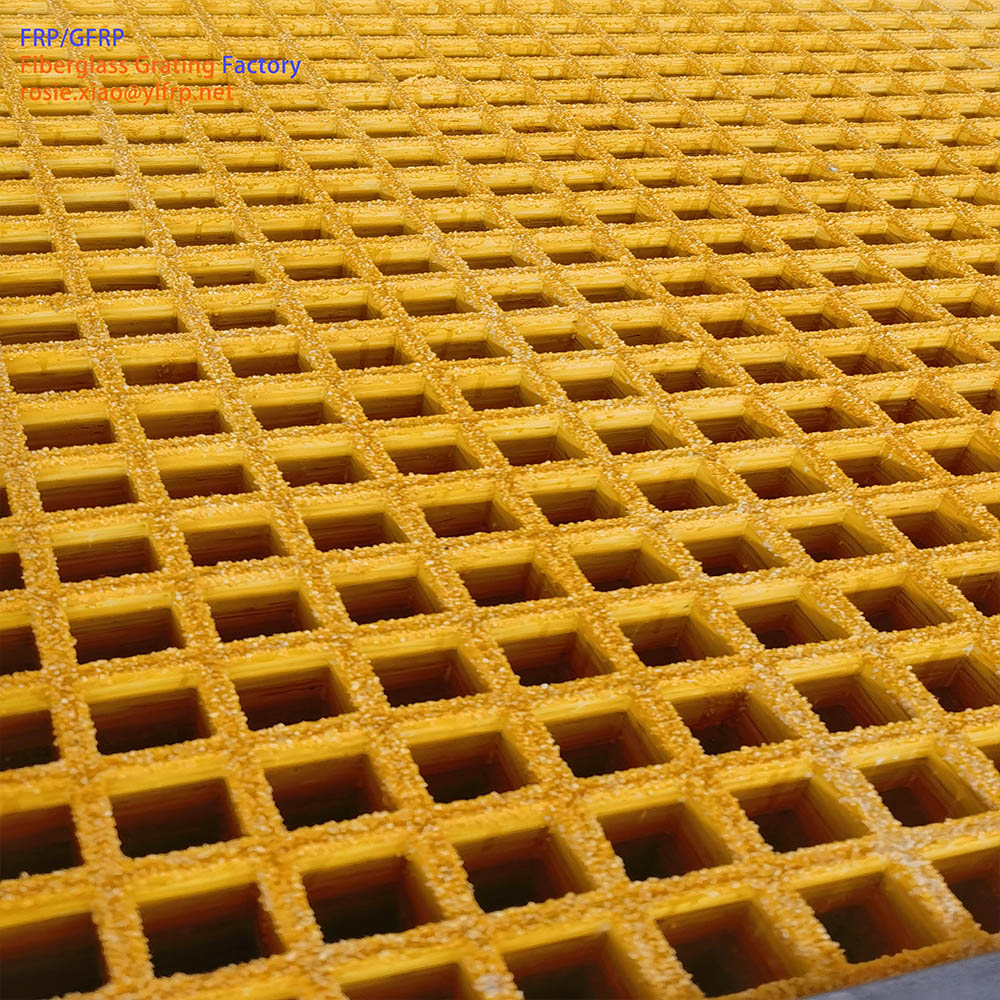

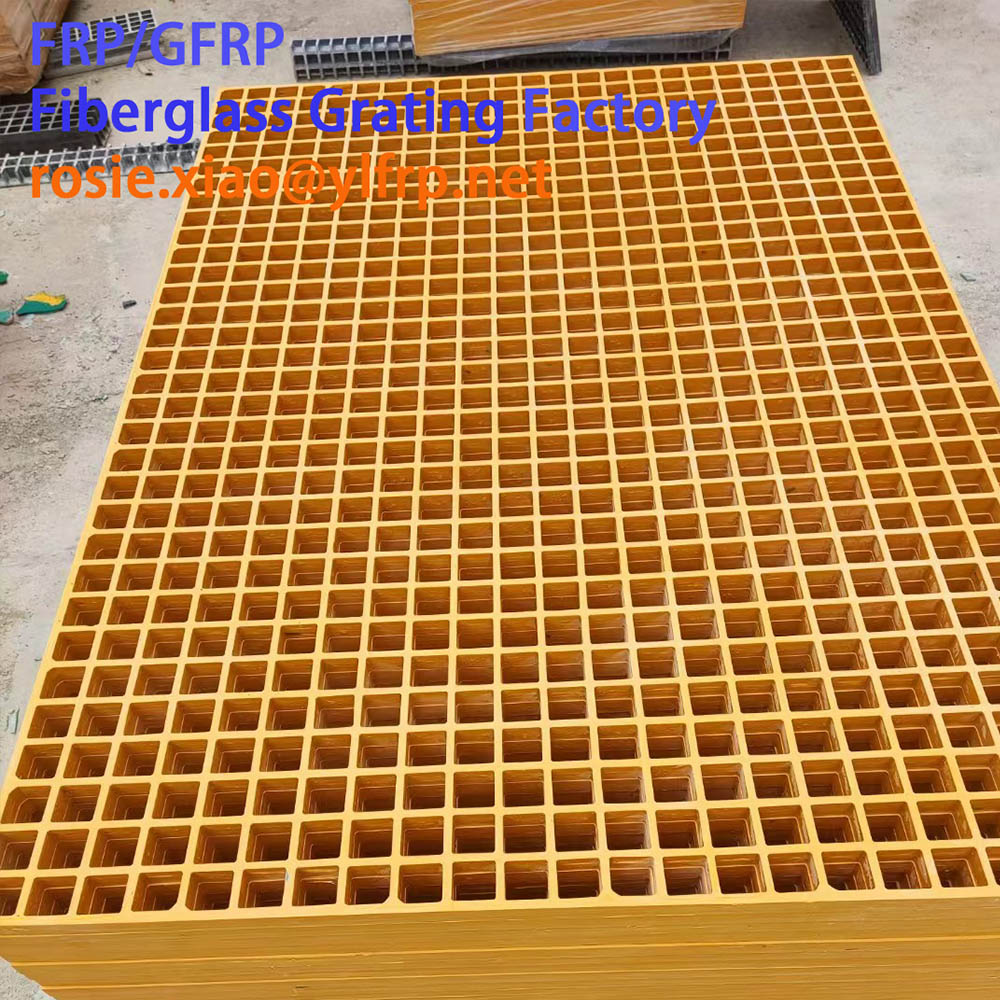

FRP Fiberglass grating for solar rooftop walkways light weight Floor Grills for pigeon lofts

Many applications require solid flooring for a variety of reasons, such as outdoor control in a wastewater plant, an offshore drilling mud room, or possibly for safety reasons to prevent small objects from falling through the floor to the level below. For these instances, YULONG composite offers FRP fiberglass plate grating solutions. Fiberglass reinforced plastic (FRP) solutions and anti-slip materials are one of our main supplies.

Hubei Yulong have constantly evolved our offerings in FRP grating, ladders, handrails and more. In line with this, we have grown in proficiency and capability in providing unique FRP solutions to a diversified range of industries like marine, mining, public infrastructure, oil and gas, and food and beverage sectors to name a few. The advancement of our products made from this unique anti-slip material is aimed at securing extended design life in different types of applications.

In turn, this enables us to aid our continuing commitment to add more value to our customers undertakings.

* Strong, Lightweight and Corrosion-Resistant Molded FRP Grating has the strength of steel, but will not degrade. FRP Grating is also acid and oil resistant.

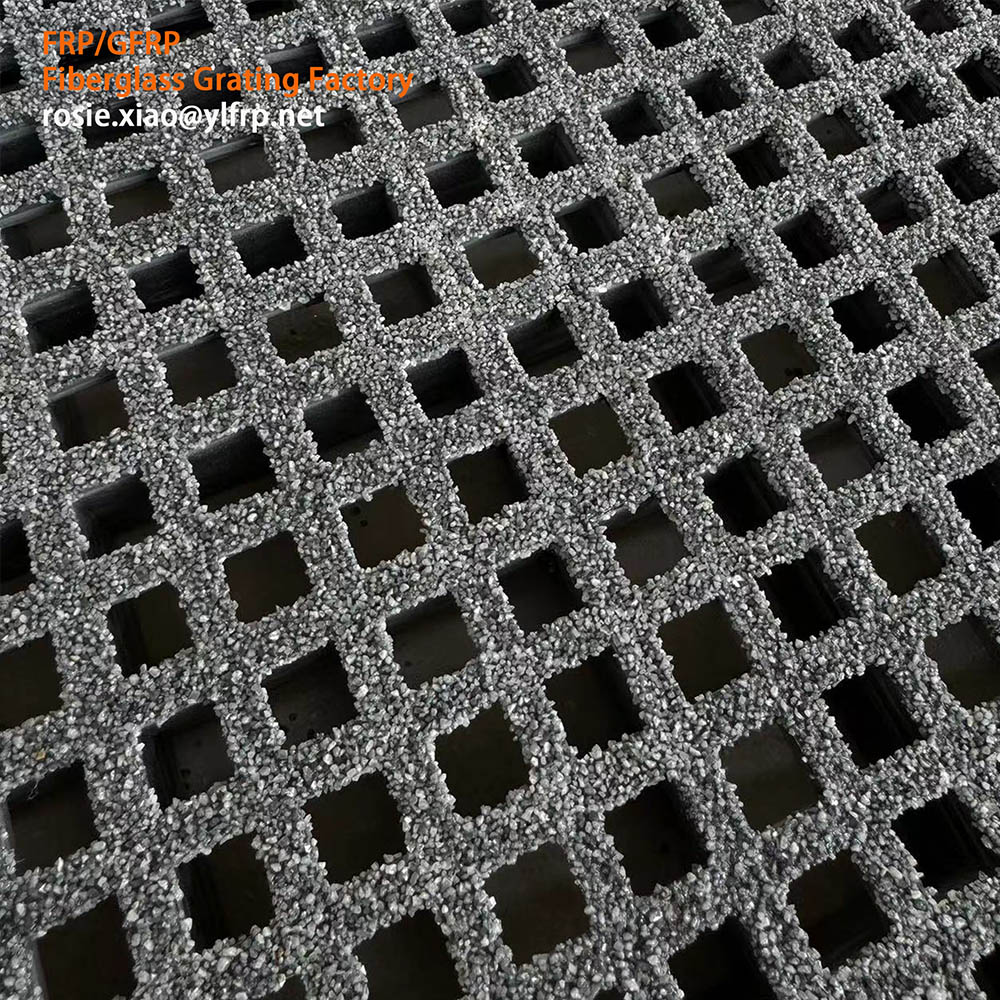

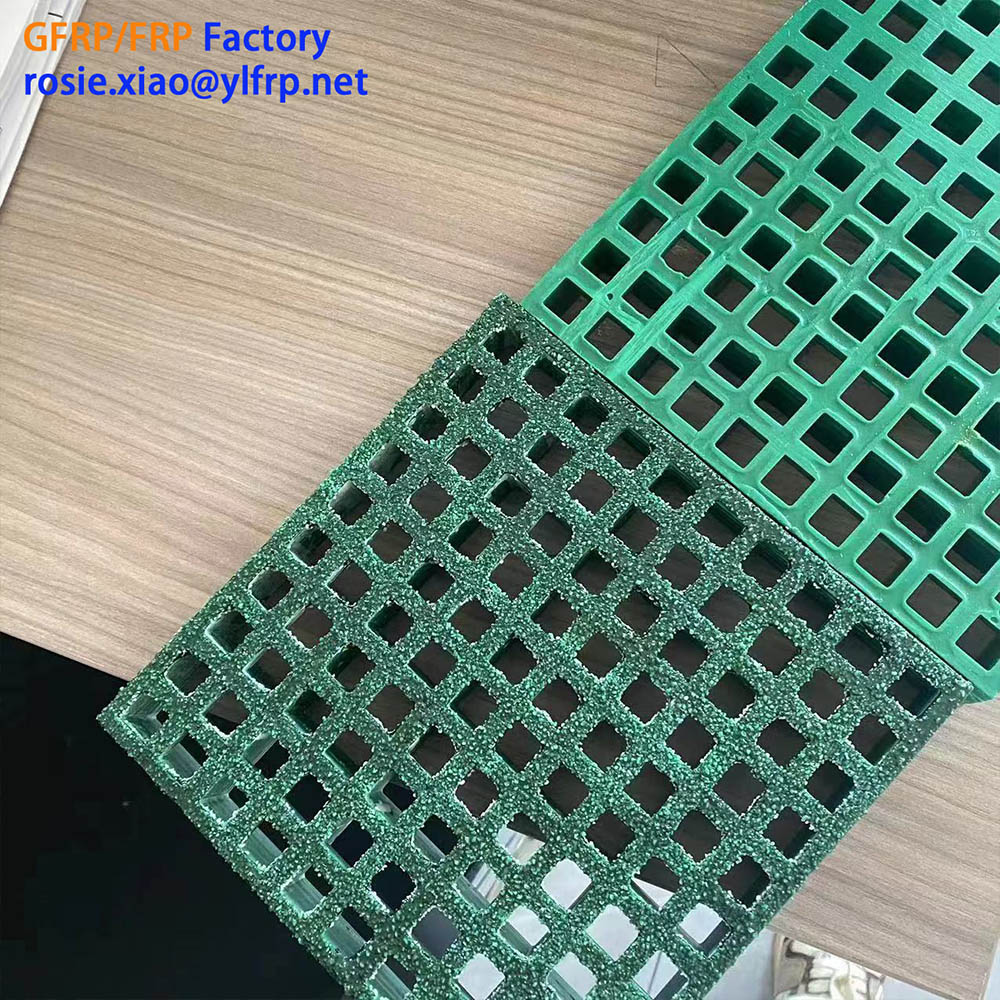

* Safer Walking Surface for Trench Covers and Fiberglass Walkways A coarse, gritted epoxy coating enhances traction.

* Support and Stability Molded Fiberglass Grating Panels are equally strong in both directions

* Easy Fabrication FRP grating panels are lightweight, easy to transport, and can be cut and fabricated using standard hand tools.

* Extended Life The resin surface increases resistance to chemical corrosion and is not affected continuous UV exposure.

|

Molded Fiberglass FRP Grating Parameters |

|

|

Type |

Molded FRP Grating |

|

Material |

Fiberglass + Resin base (ORTHO, ISO, VE) +Filler (ATH, CAO) |

|

Size |

38*38*38mm,40*40*40mm, 19*19*30mm, etc. can be customized |

|

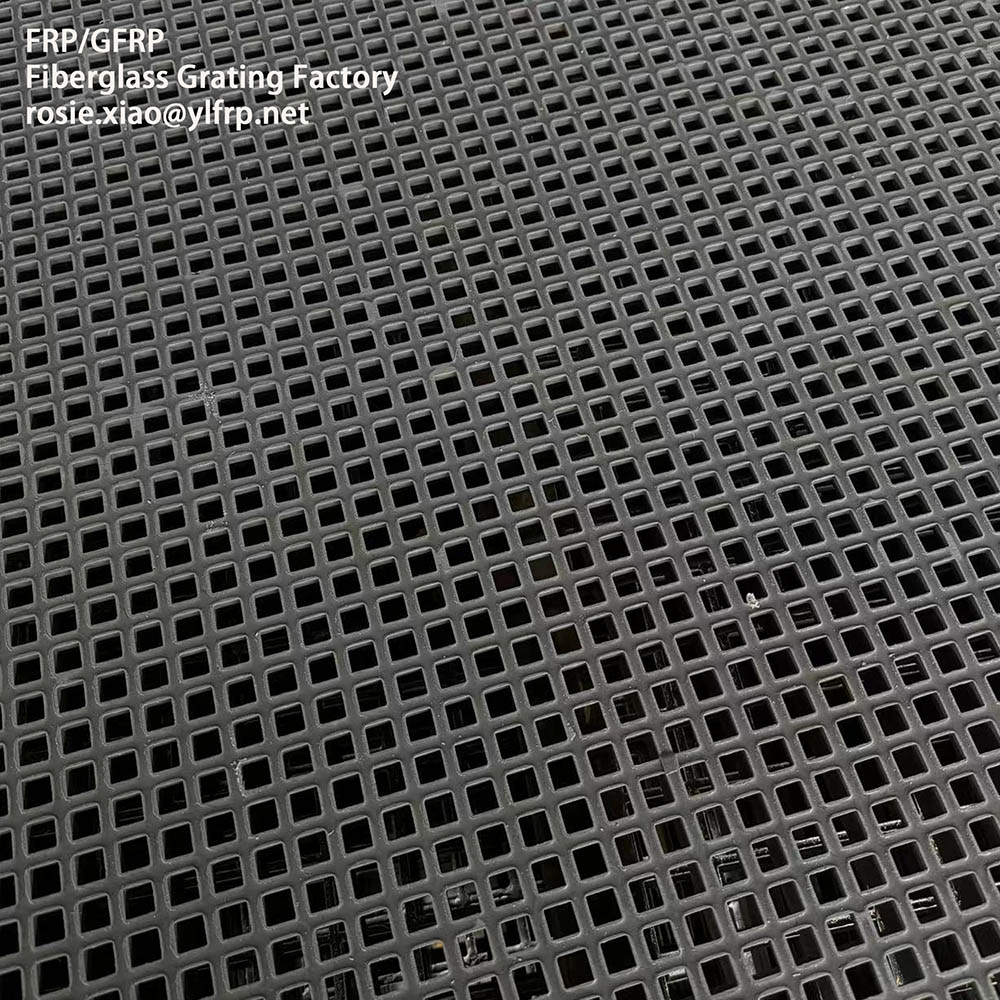

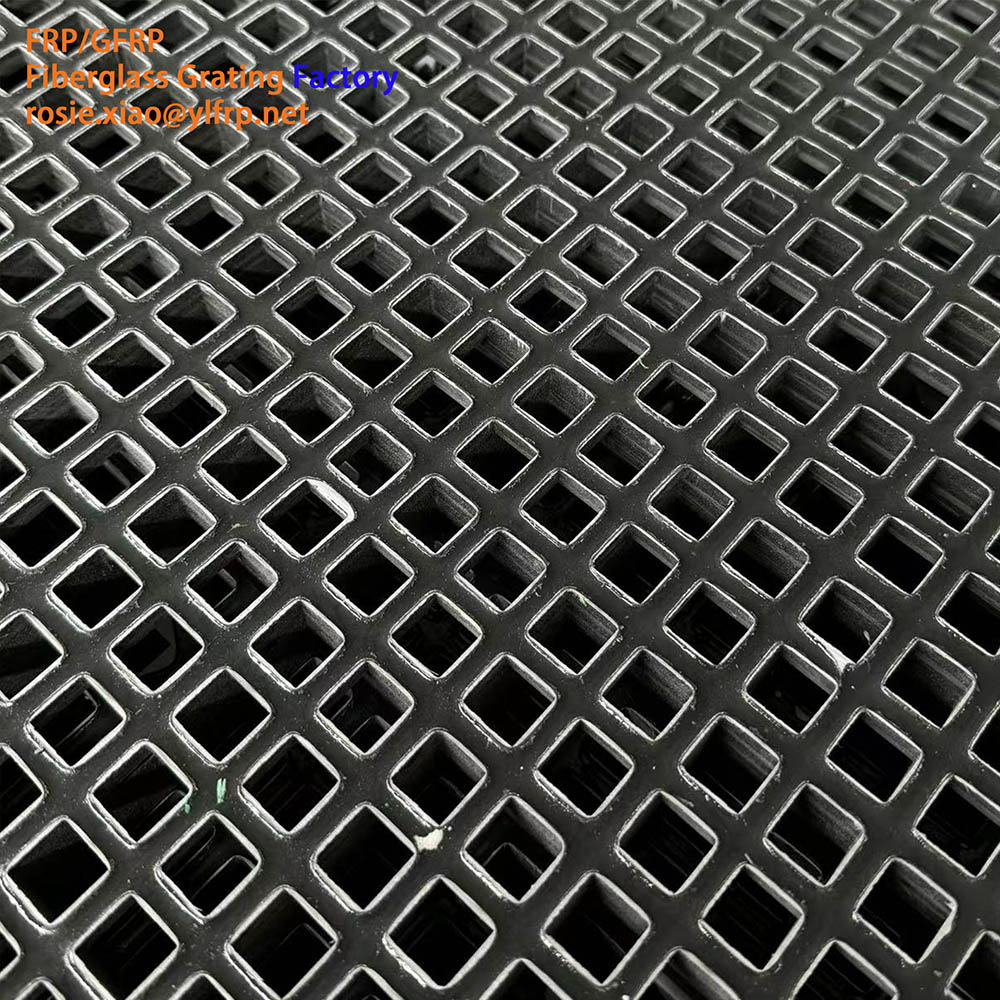

Color |

Yellow, Orange, Blue, Green, Grey, etc. can be customized |

|

Surface |

Concaved |

|

Properties rosie.xiao@ylfrp.net WhatsApp +86-13477858967 |

|

|

Light Weight, High Strength |

Low Density (about 1.8), 1/4 of steel ,2/3 of aluminum. Specific strength is superior to ordinary carbon steel. Anti-creeping. Impact endurance. |

|

Safety |

Good performance of electric insulation. 10KV no voltage breakdown. No electro-magnetic behavior. No electric spark. Oxygen |

|

|

index≥32, Anti-fire and Pass test of ASTM-E84. |

|

Anti-Corrosion |

No rust, resistance to acid, alkali, organic dissolvent and other gas and liquid mixture. It has predominant advantages in anti-corrosion field. |

|

Anti-skid |

Different process mode on surface, concave, gritted, increase friction factor. Have good anti-skid function. |

|

Anti-aging |

Have more than 20 years effective service life under normal outdoor working condition. |

|

Anti-fatigue |

Moderate flexibility reduces the workers` pressure on legs and waist which is more comfortable |

|

Attractive appearance & easy maintenance |

have alternative and bright colors. Non-fading. Easily for clean. |

|

Excellent economic benefits’ |

Excellent comprehensive economic benefits |

Resin Type Comparison & Conclusion

Vinyl Ester (Type V)

Best for: Harsh chemical exposure (acids, caustics) in chemical plants, wastewater treatment, or plating.

Key Properties: Highest chemical stability, low water absorption, high strength/stiffness in seawater.

Isophthalic Polyester (Type D)

Best for: Occasional chemical splashes/spills (industrial settings).

Limitation: Less resistant than vinyl ester for prolonged chemical contact.

Food Grade Isophthalic (Type F)

Best for: Food/beverage industries with frequent wetting or cleaning chemicals.

General Purpose (Type GPI)

Best for: Cost-effective use in mild environments (walkways, dairies).

Fire-Retardant (Type XFR)

Best for: High-fire-risk areas (welding, sparking equipment).

Phenolic (Type P)

Best for: Critical fire/smoke/toxic fume resistance (oil refineries, tunnels).

Conclusion

For seawater or harsh chemical immersion, vinyl ester (Type V) is superior due to its:

Lower water diffusion (slower moisture uptake).

Higher chemical stability.

Better retention of stiffness/strength.

For fire-critical applications, phenolic (Type P) or XFR isophthalic are preferred. For cost-sensitive, low-chemical-exposure uses, GPI or Type D suffice.

Final Recommendation: Prioritize vinyl ester for durability in corrosive/water-exposed environments, and match other resins to specific needs (fire resistance, food safety, or budget).

Welcome email us for price support. rosie.xiao@ylfrp.net WhatsApp +86-13477858967

Keyword: fiberglass grating, frp grating, molded fiberglass grating, grp grating, frp grate, molded frp grating, fiberglass walkway grating